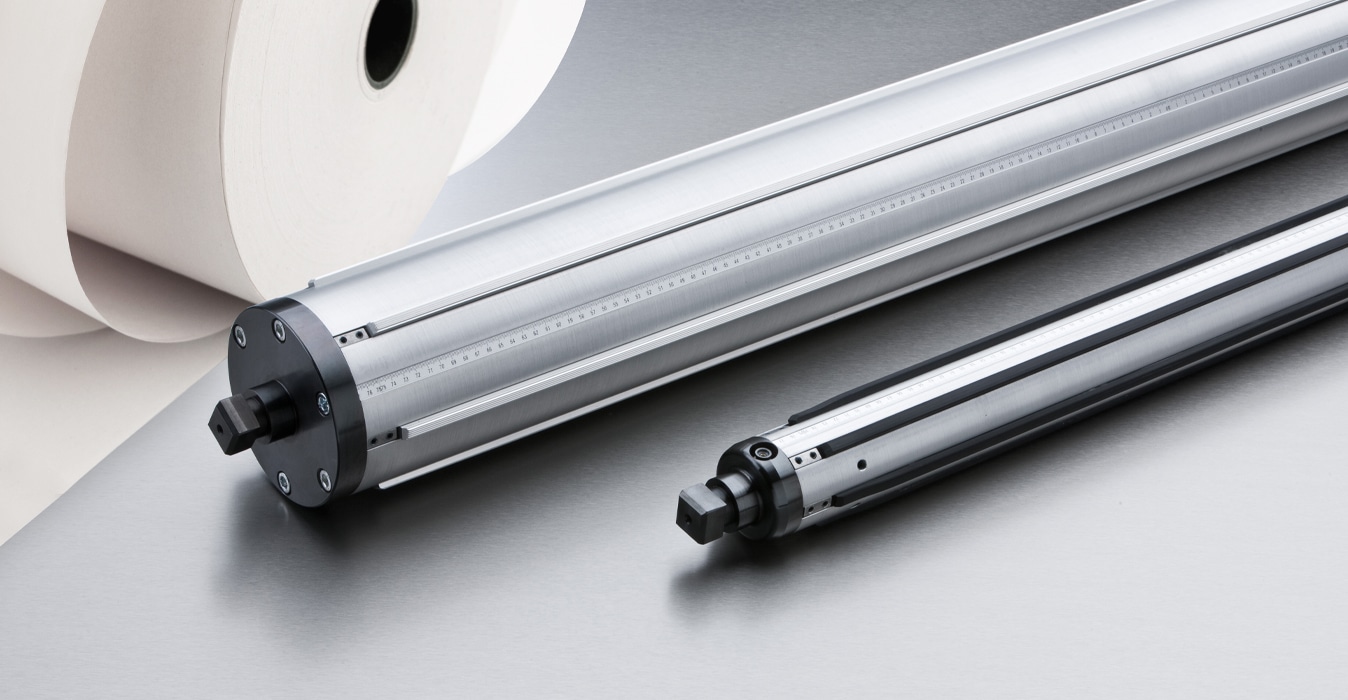

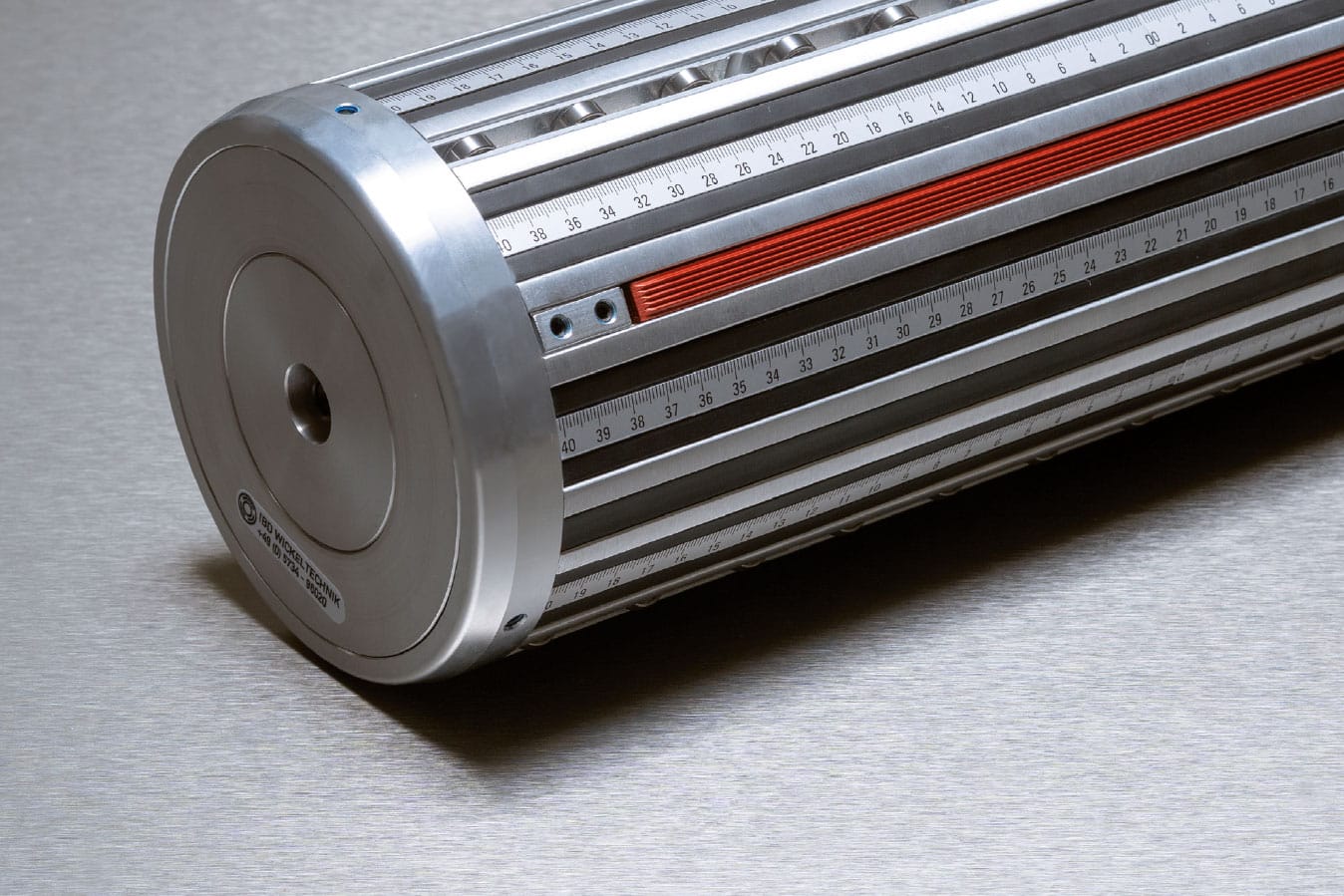

IBD expansion shaft with shell system. The new 6″ design

Skuehne2023-10-10T08:28:45+02:00The aluminium profile winding shaft with clamping shells was developed especially for coreless winding and for the use with thin-walled cores. The core-protecting characteristic of this design makes the shaft very interesting for many industrial sectors. Due to the aluminium profile the expansion shaft is extreme light. In addition to the already existing 3" diameter, the new 6" diameter enables a much higher load capacity. Both expansion shafts can also be ordered with material clamping for coreless applications. The shell expansion shafts are available with standard journals, journals on customers request or as a flanged version for cantilever [...]