AT series linear actuators

This solution is generally adopted in highly compact machines including an unwind or rewind station. Assembly can be performed with frontal flange, foot or joints. Axial actuators, or with ratio motors, are available to reduce the space required or to increase the thrust force. The operator can determine the speed with the web@path control menu. The reed electronic limit switch are inserted in the slots of the stem and are easy to access to change the stroke of the actuator.

Wyślij zapytanie o cenę online

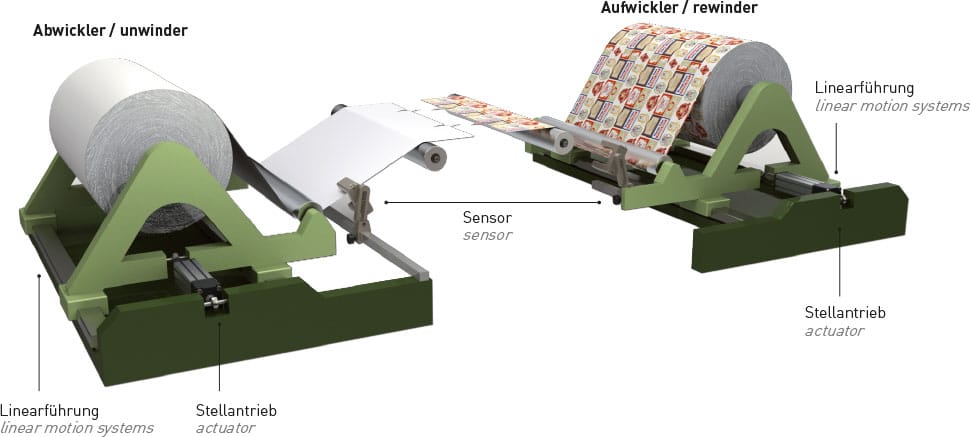

Shifting guide for unwind stations

On unwinding phase the sensor reads the edge or the true line of the web to align it correctly before the following process. It is advisable to secure the sensor near the last unwind guide roller, but still connected to the fixed part of the machine.

Shifting guide for rewind stations

During rewinding the sensor is applied directly on the rewinder so that it can correct the position of the material in outfeed from the process in real time to produce a reel with a straight profile.

Technical data

| AT.53 | AT.103 | AT.203 | |

|---|---|---|---|

| R | R | ||

| Stroke (mm) | ± 25 | ± 50 | ± 100 |

| Min – max speed (mm/s) | 4,5 – 75 | 4,5 – 75 | 4,5 – 75 |

| Max force (N) | 1400 | 1400 | 1400 |

| force at 20 mm/sec (N) | 800 | 800 | 800 |

This information is correct at date of pubblication, but is subject to change without prior notification, or as required by IBD Wickeltechnik GmbH