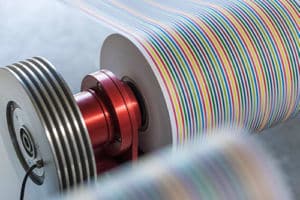

Sensor roller CPF

The sensor roller of CPF series is recommended for the web tension reading during the web processing. The roller sensor CPF has an high precision in detecting the web tension also because the position of the material on the roller doesn’t affect the reading. The roller is fixed quickly and easily from one side only and the connector could be installed both inside or outside the machine.

On request, a version without integrated amplifier and display on the front of the roller is available .

| Code | load (N) | dimensions mm | ||

| L = 250 – 300 ØD = 80 |

L = 300 – 500 ØD = 100 |

L = 350 – 600 ØD = 120 |

||

| CPF.5 | 50 | o | x | x |

| CPF.10 | 100 | o | x | x |

| CPF.20 | 200 | o | o | o |

| CPF.40 | 400 | o | o | o |

| CPF.70 | 700 | x | o | o |

different size available on request

Start Request

Price Inquiry

Inquire online now and receive a non-binding offer in 24 hours.

Start Request