Magnetic Powder Brakes

Our electromagnetic powder brakes and clutches are some of our most tested and improved products and are in production for more than 20 years. Our brakes and clutches have been upgraded recently in order to offer innovative products that guarantee extremely low residual torque.

The features

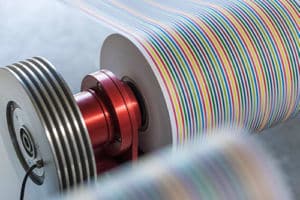

For these reasons, they are particularly suitable to use in the printing sector, flexographic and rotogravure machines, but also in food preparation areas or locations with stringent hygiene and dust emission tolerances. Because of their very low residual torque, they are ideal to use in the food packaging sector, on laminating or plastic film machines and for all applications with low web tension.

Price Inquiry

Operating Principle

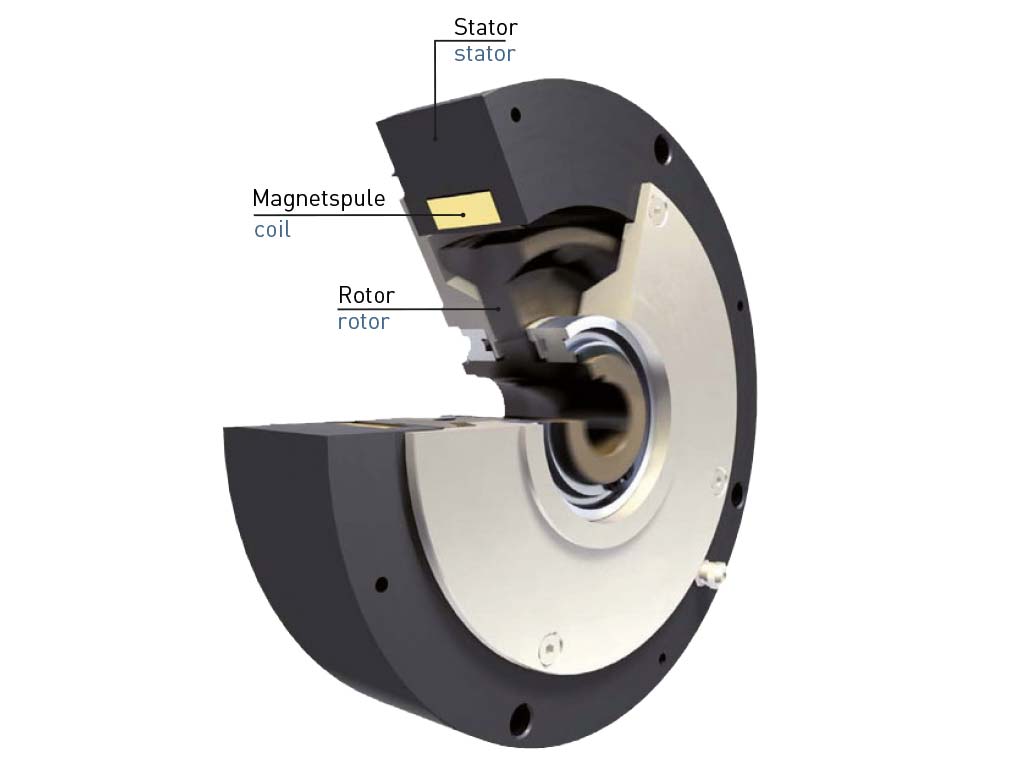

The electromagnetic powder brake consists of three basic components: a coil, a stator and a rotor.

When electric current is supplied to the brake, the magnetic field inside the coil starts to vary in proportion to the size of the current. The variations in the magnetic field alter the viscosity of the special powder positioned between the rotor and the stator.

When an electrical current is applied to the coil, the particles are aligned along the magnetic field force lines, create a dragging bond between the rotor and the stator and generate thereby the braking effect. When the current is disconnected, the powder is pushed against the stator by the centrifugal force, thus releasing

the rotor so that it can rotate.

The particles aligned along the magnetic field force lines and create a dragging bond between the rotor and the stator.

When this magnetic field is removed, the particles are pushed towards the stator by the centrifugal force.

Technical Data

| Model | |

|---|---|

| Serie B.121 | [ download ] |

| Serie B.351 | [ download ] |

| Serie B.651 | [ download ] |

| Serie B.1201 | [ download ] |

| Serie B.1701 | [ download ] |

| Serie B.2500 | [ download ] |

| Serie B.5000 | [ download ] |